STEP 1: EDGE MILLING

Process that secures the weldability of SAW by milling both longitudinal edges of plates with groove type (X or Y shaped)

STEP2: PRE – BENDING

Process that forms both edges of plate in their optimal curvature by using press and tool

STEP3: PRESS– BENDING

Process that forms the entire body of plate in its optimal external diameter by using press and tool

STEP4: GAP CLOSING PRESS ( POST– BENDING )

Process that minimizes the open gap (the distance between two edges) by using press

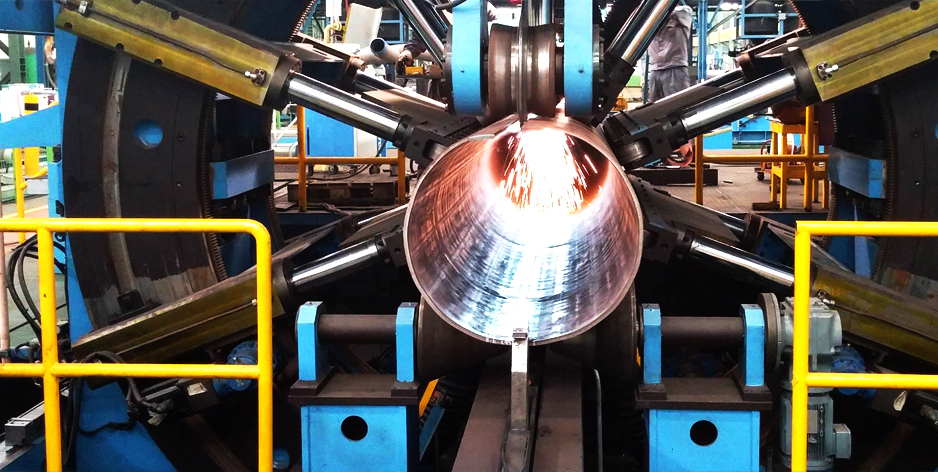

STEP5: TACK WELDING

Process to secure the original form through fitting-up (GMAW) two edges of completely formed product

STEP6: INTERNAL WELDING

Process to weld inside grooved edge of formed pipe by SAW method

STEP7: LONGITUDINAL SEAM MILLING (GAUGING)

Process to remove tack welds by milling

STEP8: EXTERNAL WELDING

Process to weld outside grooved edge of formed pipe by SAW method

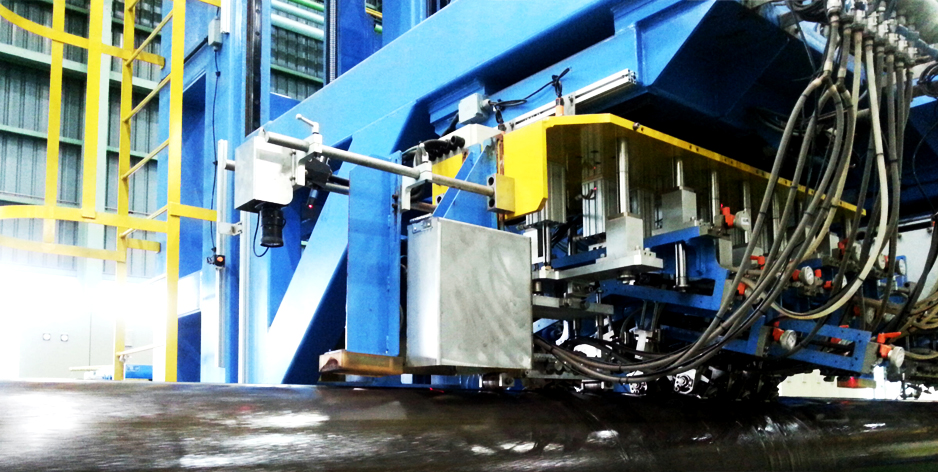

STEP9: ULTRASONIC TEST

Process to examine whether there are defects in welds (crack, air hole, slag, etc.)by using ultrasonic waves before cold expanding

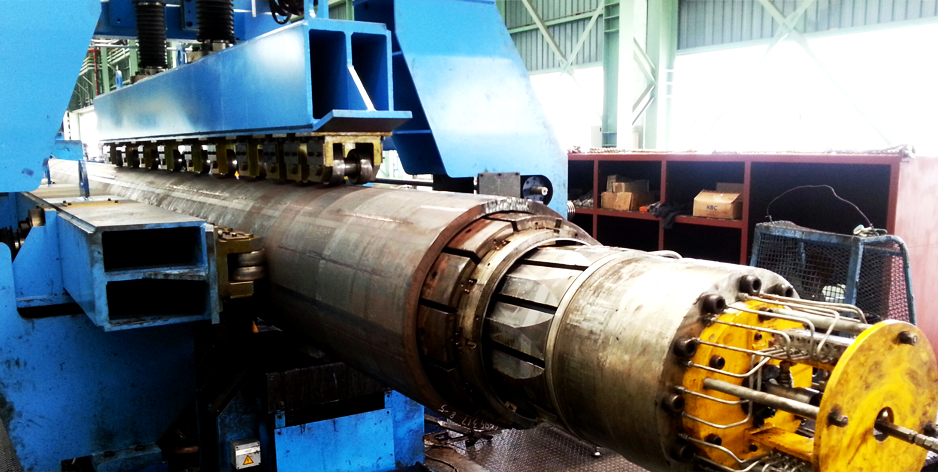

STEP10: FULL LENGTH COLD EXPANDER

Process that cold-expand pipe’s O.D from inside of pipe in order to calibrate pipe dimension and to reduce residual stress of pipe

STEP11: END FACING

Process to machine both pipe ends as per customers’ requirements

STEP12: HYDROSTATIC TEST

Process to test pipe hydrostatically with constant pressure and holding time

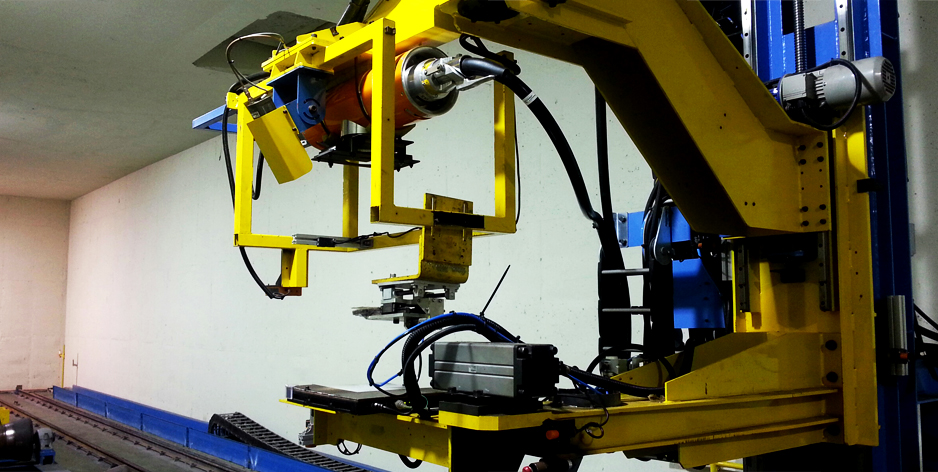

STEP13: ULTRASONIC TEST

Process to examine whether there are defects in welds (crack, air hole, slag, etc.)by using ultrasonic waves after cold expanding.

STEP14: ULTRASONIC TEST

Process to examine whether there are defects in welds (crack, air hole, slag, etc.)by using the radiation (X-ray)

STEP15: PIPE END RADIOGRAPHIC TEST

Process to examine whether there are defects in welds of both pipe ends by using the radiation (X-ray)

STEP16: HEAT TREATMENT

Process to heat-treat entire pipe in order to get required properties (depending on type of heat treatment)

STEP17: MILL COATING

Process that prevents corrosion by spreading inhibited oil on product surface